Batteries

We scrutinize the batteries not only in terms of energy density but also longevity, load characteristics, maintenance requirements, self-discharge, and operational costs. We are well aware of customer needs and have responded by offering packs that best suit the specific applications. Emphasis is placed on the small size, high energy density, and low price. With a focus on identifying problems and developing solutions for tough battery applications, we offer

1. Automotive batteries 2. Industrial batteries 3. Inverter batteries 4. Low maintenance batteries 5. Maintenance free batteries

Automotive Batteries

Backed by a team of well-versed professionals, we bring for our clients a wide assortment of Automotive Low Maintenance Batteries. Our entire range has been designed and incorporated with modern features as per industry standards and requirements that are capable of high performance. These batteries are resistant to corrosion, abrasion and diverse climatic conditions. Our Low Maintenance Batteries delivers the power and lifecycle associated with a standard battery. The hybrid grid alloys allow extended watering intervals. New separators and internal construction reduce the gassing, minimizing the water loss. Low antimonial selenium plus lead alloy grids feature increased electrolyte capacity for consistent power supply. We have engineered Low Maintenance Automotive Batteries for use in different automotive including Car, Tractor and Truck.

Car Battery

Description

We offer Low Maintenance Car Batteries made of a premium alloy composition imported from PASMINCO Australia. This amazingly special high-grade alloy provides extra strength and improved resistance to corrosion. These batteries are specially designed to satisfy the demand for low maintenance, less frequent top-ups and longer life.

Features

- Well-designed 'Positive plates' provide maximum surface area for high power and voltage endurance.

- Special computerized design of the 'Negative Plates' provides perfect balance along with the positive, thus giving maximum performance.

- Rugged POLYPROPYLENE containers assist in high impact resistance.

- Fine pores of polyethylene envelopes separators help in the free electrolyte movement between the positive and the negative plates. This enhances the cold cranking ability of the battery. Problems of internal short-circuits are also eliminated easily.

- The unique thorough partition, resistance welded Intercell connections, dramatically shortens the power path and minimizes voltage drop on cranking.

- The heavy-duty plate density provides increased plate strength. A special chemical formulation drastically reduces sulphation, allowing full recharging and significan

Specifications

| Type | Layout | Capacity | Max Dimensions (mm) | Weight | Chg. Amps | |||

| C20 | C5 | L | W | H | Dry (Kg.) | |||

| AL-40Z | R/L | 35 | 28 | 195 | 127 | 223 | 7.5 | 3 |

| AL-60 | R | 45 | 36 | 235 | 127 | 223 | 8.3 | 3.5 |

| 65D26R | R | 60 | 48 | 257 | 170 | 224 | 13.9 | 4 |

| 75D31R | R/L | 75 | 60 | 302 | 171 | 225 | 16.5 | 4.8 |

| DIN44 | L | 44 | 35 | 210 | 174 | 190 | 11 | 4 |

| DIN55 | L | 55 | 44 | 242 | 174 | 190 | 13.5 | 4 |

| DIN66 | L | 66 | 52 | 315 | 174 | 190 | 15.5 | 4.5 |

| DIN72 | L | 72 | 57 | 315 | 174 | 190 | 17.5 | 5 |

Tractor Battery

Description

Our range of Tractor Batteries are manufactured using world class technology and stringent quality control parameters for lasting performance. The robust plate design and ribbed container make these batteries ideal for applications on a rough terrain under extreme conditions. A labyrinth of the duplex cover makes battery safer and leak proof.

Benefits

- Low eight & high output density

- Low maintenance & cost efficient

- Shock proof

- Long battery life

- Nation wide availability

Features

- Specially manufactured for application in trucks

- Leak proof design with heat sealed container & cover

- Uniform Flat surface, thin Plates for High cranking ability

- Special alloy grid for low maintenance & excellent performance in all terrain conditions

- Aesthetically designed container and cover made of PP co-polymer for strength & durability

- Special paste formulation for Long life & high cranking performance

- PE envelops with glassmat separators for low internal resistance, high vibration resistance and avoid internal short

- Thro'partititon welded for short electrical path-reduces internal resistance and increased cranking performance

Specifications

| Type | Layout | Capacity | Max Dimensions (mm) | Weight | Chg. Amps | |||

| C20 | C5 | L | W | H | Dry (Kg.) | |||

| AL80T | R/L | 75 | 60 | 302 | 171 | 225 | 16.5 | 4.8 |

| AL88 | L | 88 | 70 | 404 | 173 | 223 | 19.5 | 5.5 |

| AL950T | L | 95 | 76 | 404 | 173 | 223 | 19.5 | 5.5 |

| AL110 | L | 110 | 88 | 404 | 173 | 223 | 22 | 5.5 |

Truck Battery

Description

We offer high performance Truck Batteries that feature long life, high cranking power and minimum maintenance. The robust plate design and ribbed containers make these batteries resistant for shocks and vibration. Our range of Truck Batteries are manufactured employing stringent quality control norms to ensure performance even under extreme working conditions.

Benefits

- Low weight and high output density

- Low maintenance and cost efficient

- Unbelievably low price

- Shock and vibration proof

- Long battery life

Features

- Specially manufactured for application in trucks

- Leak proof design with heat sealed container & cover

- Uniform Flat surface, thin Plates for High cranking ability

- Special alloy grid for low maintenance & excellent performance in all terrain conditions

- Aesthetically designed container and cover made of PP co-polymer for strength & durability

- Special paste formulation for Long life & high cranking performance

- PE envelops with glassmat separators for low internal resistance, high vibration resistance and avoid internal short

- Thro'partititon welded for short electrical path-reduces internal resistance and increased cranking performance

Specifications

| Type | Layout | Capacity | Max Dimensions (mm) | Weight | Chg. Amps | |||

| C20 | C5 | L | W | H | Dry (Kg.) | |||

| AL120 | 3R | 120 | 96 | 502 | 182 | 255 | 26 | 5 |

| AL150 | 3R | 150 | 120 | 504 | 218 | 255 | 31 | 7.5 |

| AL165 | 3R | 165 | 132 | 515 | 274 | 266 | 34 | 9.6 |

| AL180 | 3R | 180 | 145 | 515 | 274 | 266 | 36 | 9.6 |

Industrial Batterie

We are one of the most trusted names for designing and developing a wide variety of traction cells. Apart from this, we also have comprehensive OEM, pack development, design and assemble capabilities. We make sure that the performance of our complete range of qualitative industrial batteries is up to the mark and our valued clients have no complaints.

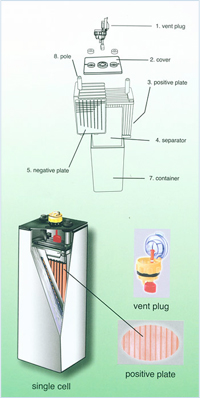

Traction Cells

Our range of traction cells are used to provide motive power for electric or hybrid vehicles such as a forklift, golf cart, etc. Designed with a high ampere-hour capacity, these industrial traction cells feature optimized weight to volume (power density), and weight to power ratios (lb/AH+). We offer high-quality industrial traction cells with low internal resistance for improved battery performance.

Components

- Vent Plug : The design of vent plug allows easy checking of electrolyte level. One can also check the level of electrolyte while pouring the electrolyte in the container.

- Cover : The perfectly sealed cover of the battery is made of Poly Propylene Copolymer.

- Positive Plate : The positive plate consists of grid made of lead alloy, a polyester or fiber tube mounted onto each core metal of grid, active material filled between the tube and the core metal. The positive plate has high performance and long life.

- Separator : The separator is made of poly ethylene envelope heavy duty type which provide excellent resistance to acid and prevents oxidation.

- Negative Plate : The negative plate consists of grid made of lead alloy and active material pasted in the grid.

- Electrolyte : The electrolyte is refined with diluted sulfuric acid. The maximum specific gravity is 1.280 ± 0.01 at 20°C.

- Container : The container is made of Poly propylene copolymer, which has excellent dimensional stability, more

vibration resistance and greater impact resistance.

- Pole : The Pole is made of lead alloy.

vibration resistance and greater impact resistance.

Specifications

| Cell Type | Ah @ C5 at 300C | Length mm | Dry Wt. Kg. | Acid Vol. Ltr. | Filled Wt. Kg. |

| Positive Plate Capacity 21 Ah. Overall Height 231 mm Height Upto Lid Top 201 mm | |||||

| 2-AL-BTB 42 | 42 | 47 | 3.3 | 0.7 | 4.2 |

| 3-AL-BTB 63 | 63 | 61 | 4.4 | 1 | 5.7 |

| 4-AL-BTB 84 | 84 | 77 | 5.5 | 1.3 | 7.2 |

| 5-AL-BTB 105 | 105 | 93 | 6.6 | 1.6 | 8.6 |

| 6-AL-BTB 126 | 126 | 109 | 7.7 | 1.9 | 10.1 |

| 7-AL-BTB 147 | 147 | 125 | 8.8 | 2.2 | 11.5 |

| 8-AL-BTB 168 | 168 | 141 | 9.9 | 2.5 | 13.1 |

| 9-AL-BTB 189 | 189 | 157 | 11.6 | 2.7 | 15.1 |

| 10-AL-BTB 210 | 210 | 173 | 12.7 | 3 | 16.6 |

| 11-AL-BTB 231 | 231 | 189 | 13.8 | 3.3 | 18.1 |

| 12-AL-BTB 252 | 252 | 205 | 14.9 | 3.6 | 19.5 |

| 13-AL-BTB 273 | 273 | 221 | 15.9 | 3.9 | 21 |

| Cell Type | Ah @ C5 at 300C | Length mm | Dry Wt. Kg. | Acid Vol. Ltr. | Filled Wt. Kg. |

| Positive Plate Capacity 32 Ah. Overall Height 290 mm Height Upto Lid Top 260 mm | |||||

| 2-AL-BTB 64 | 64 | 47 | 4.3 | 1 | 5.5 |

| 3-AL-BTB 96 | 96 | 61 | 5.9 | 1.3 | 7.6 |

| 4-AL-BTB 128 | 128 | 77 | 7.5 | 1.7 | 9.8 |

| 5-AL-BTB 160 | 160 | 93 | 9.2 | 2.1 | 11.8 |

| 6-AL-BTB 192 | 192 | 109 | 10.8 | 2.5 | 14 |

| 7-AL-BTB 224 | 224 | 125 | 12.5 | 2.8 | 16.1 |

| 8-AL-BTB 256 | 256 | 141 | 14.1 | 3.2 | 18.3 |

| 9-AL-BTB 288 | 288 | 157 | 16.4 | 3.6 | 21 |

| 10-AL-BTB 320 | 320 | 173 | 18 | 4 | 23.1 |

| 11-AL-BTB 352 | 352 | 189 | 19.7 | 4.4 | 25.3 |

| 12-AL-BTB 384 | 384 | 205 | 21.3 | 4.7 | 27.4 |

| 13-AL-BTB 416 | 416 | 221 | 22.9 | 5.1 | 29.5 |

| Cell Type | Ah @ C5 at 300C | Length mm | Dry Wt. Kg. | Acid Vol. Ltr. | Filled Wt. Kg. |

| Positive Plate Capacity 42 Ah. Overall Height 353 mm Height Upto Lid Top 323 mm | |||||

| 2-AL-BTB 84 | 84 | 47 | 5.3 | 1.3 | 6.9 |

| 3-AL-BTB 126 | 126 | 61 | 7.4 | 1.8 | 9.7 |

| 4-AL-BTB 168 | 168 | 77 | 9.5 | 2.3 | 12.5 |

| 5-AL-BTB 210 | 210 | 93 | 11.6 | 2.8 | 15.2 |

| 6-AL-BTB 252 | 252 | 109 | 13.7 | 3.3 | 18 |

| 7-AL-BTB 294 | 294 | 125 | 15.8 | 3.8 | 20.7 |

| 8-AL-BTB 336 | 336 | 141 | 18 | 4.3 | 23.6 |

| 9-AL-BTB 378 | 378 | 157 | 20.7 | 4.8 | 26.9 |

| 10-AL-BTB 420 | 420 | 173 | 22.8 | 5.3 | 29.7 |

| 11-AL-BTB 462 | 462 | 189 | 24.9 | 5.8 | 32.4 |

| 12-AL-BTB 504 | 504 | 205 | 27 | 6.3 | 35.3 |

| 13-AL-BTB 546 | 546 | 221 | 29.1 | 6.8 | 37.9 |

About Us

Over the years the HP ENTERPRISES has spread its wings over various continents Nigeria, India, and the UK employing over 1000 people.

MoreQuick Menu

Address

PLOT NO 24,26 &27/3,

NEAR WIMCO NAKA MIDC,

AMBERNATH WEST MAHARASHTRA 421501

Direct: 91 – 251-2712196

Mobile : 91 – 79000 82000

Email : hpenterprises@rediffmail.com

HP Enterprises © 2018 All rights reserved. | Developed & Design By HP ENTERPRISES