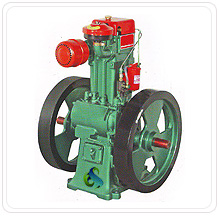

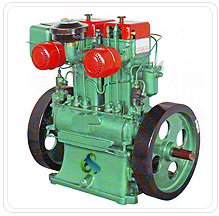

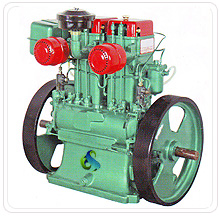

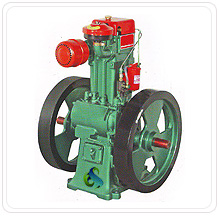

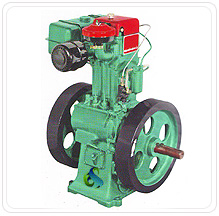

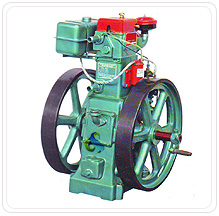

Technical Details :

Vertical Diesel Engine is rated on the effective horsepower at engine crankshaft on a maximum load for continuous running. Each engine is tested as per IS: 11170 to give a continuous rating.

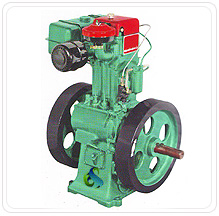

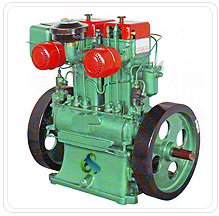

Cooling: Engine Cooling is efficiently handled by a run-through water supply. A radiator or a cooling tank could also be provided if required.

Lubrication: All internal moving parts are lubricated by splash system. In case of bush bearing type, 10 HP Engine, lubrication is by plunger type lubricating pump which is mounted below the fuel pump bracket and provides Lub. Oil to Tapper Roller Bearings & Connecting Rod big end bearing through banjo oil ring mounted on the crankshaft, parts like valves, push rod, etc. could be lubricated with the oil can.

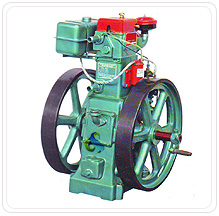

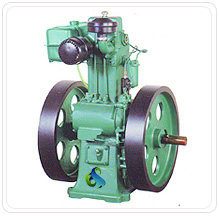

Rotation: Standard rotation is clockwise, facing flywheel keeping exhausted on the left-hand side.

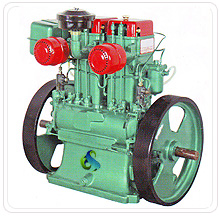

Fuel Injection Equipment :MICO (Bosch ) or USHA Fuel injection Equipment or equivalent.

Governing: A sensitive centrifugal type Governor is mounted on a camshaft gear wheel. Speed variation is controlled within a limit to comply with “B1” Class Governing as mentioned in IS: 11170.

Cylinder Liner: The Cylinder liner is Hard Chrome Plated

.

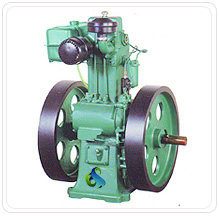

Air Cleaner: Oil bath type Air Cleaner is Provided to clean incoming air. Use of clean air increases the life of the Cylinder Liner.

Standard Equipment: Pulley, Spanner, Set, Screw Driver, Oiler, Starting Handle, Air Cleaner, Silencer, Fuel Tank, Tool Bag Instruction Manual, and Hose Nipple.

Important Note: To get efficient engine performance, the temperature of cooling water coming out from the engine head should be in between 50 C 70 C. Kindly Operate the engine at this water temperature only.